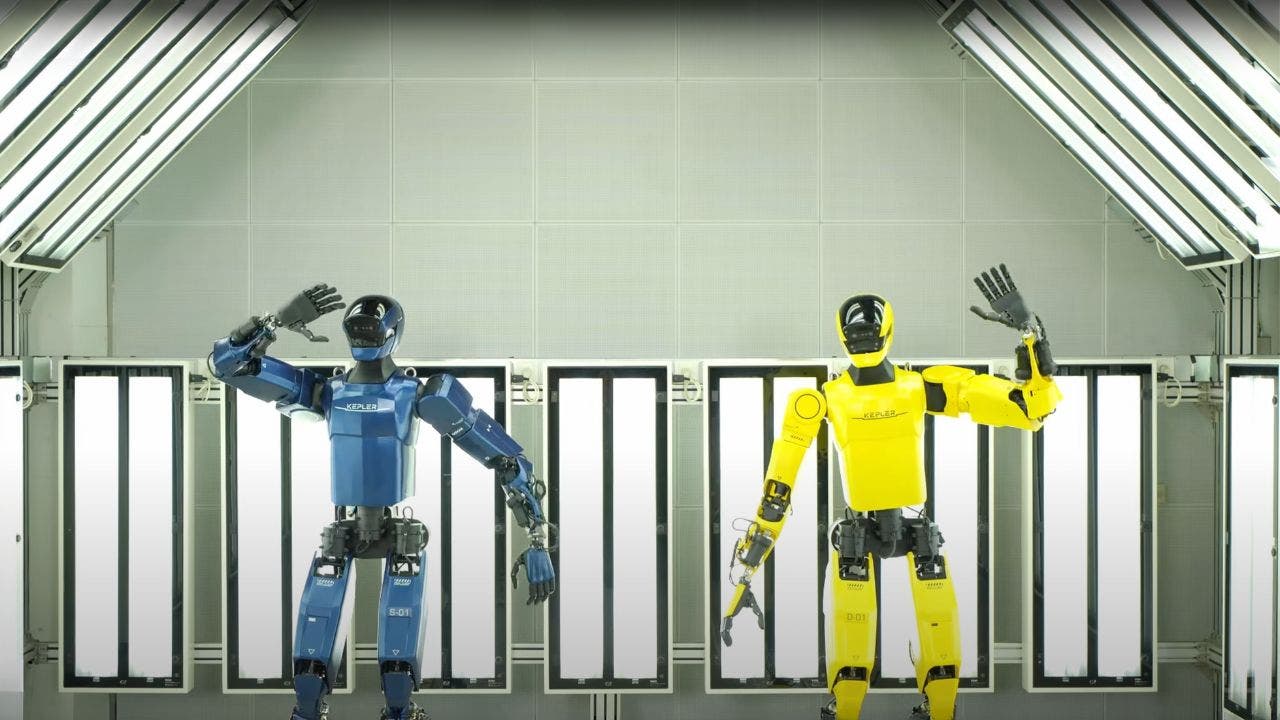

Humanoid robots handle quality checks and assembly at auto plant

Kepler Robotics has made a groundbreaking move by introducing its Forerunner K2 “Bumblebee” humanoid robot at the SAIC-GM automotive plant in Shanghai. This marks a significant moment in the deployment of advanced robotics in real-world industrial settings. In a recently released video, the K2 is showcased moving confidently through the plant, conducting detailed quality checks, and handling assembly operations that require both strength and precision. This debut signifies the beginning of scenario-based testing for Kepler’s humanoid robots across various industrial settings, where their capabilities can be evaluated in live production environments.

The K2 “Bumblebee” robot is tailored to meet the demands of modern factories. At SAIC-GM, it has already demonstrated its ability to carry out intricate inspections, navigate complex factory layouts, and manage heavy automotive components with impressive autonomy. The robot can load stamped parts, manipulate mechanical fixtures, and adapt to new tasks using a combination of imitation and reinforcement learning. Its presence in the factory highlights a shift towards smarter and more efficient production lines, where robots and human workers collaborate to achieve higher standards of quality and safety.

The Forerunner K2 represents a significant advancement from its predecessor, the K1, with substantial improvements in both hardware and software. The K2 features a reinforced limb structure for enhanced durability and maintenance ease, tactile manipulators with an impressive 11 degrees of freedom per hand, and flexible fingertip sensors that enhance its dexterity. Its integrated battery allows for up to eight hours of continuous operation, supporting the long shifts required in industrial settings.

On the intelligence front, the K2 utilizes a cloud-based cognitive system that enables it to quickly learn new tasks and coordinate its movements with full-body awareness. Enhanced perception, task planning, and improved human-robot interaction algorithms enable the K2 to operate independently while smoothly collaborating with human coworkers.

Kepler envisions its humanoid robots, including the K2, playing active roles in various industries beyond automotive manufacturing. These robots are expected to contribute to education, research, security, logistics, and hazardous outdoor operations. In classrooms, the K2 can facilitate interactive learning and real-time coaching, while in research labs, it can assist with data gathering and experimental tasks. For security applications, the robot’s advanced sensors enable it to patrol complex areas, detect emergencies, and support rescue operations.

The K2’s autonomous navigation and real-time monitoring capabilities are particularly valuable in challenging environments, including those with radiation or explosive hazards. The robot’s robust design, waterproofing, and resistance to extreme temperatures make it suitable for such conditions. Its cost efficiency, coupled with the ability to match or exceed the workload of multiple human workers in certain scenarios, positions the K2 as a practical addition to high-demand workplaces.

While the introduction of advanced humanoid robots like the K2 raises concerns about potential job displacement, experts and industry leaders emphasize that the impact is nuanced. While some jobs may be automated, new opportunities are expected to emerge alongside technological advancements. The rise of robotics is anticipated to create roles in robot maintenance, programming, AI training, and oversight, requiring different skills but essential for supporting and managing these new systems. Collaborative robots, or “cobots,” are specifically designed to work alongside humans, enhancing productivity and safety rather than simply replacing labor.

In conclusion, Kepler’s K2 humanoid robot represents a significant leap forward in the integration of advanced robotics in industrial settings. As these robots take on more tasks alongside human workers, the future of work and industry is set to be shaped by these partnerships. While concerns about potential job displacement exist, the collaborative approach between humans and machines is expected to lead to new forms of teamwork and innovation, making work environments safer and more efficient. The integration of humanoid robots is likely to shift the workforce rather than replace it entirely, opening up new possibilities for businesses and employees as they adapt to a more automated future.